Hallo Kinder! Und, wieder dabei, heute zu lernen. Das sind die speziellen Komponenten, die Öle und Wasser von hier nach dort in Maschinen bewegen sollen. Sie sind ein sehr grundlegender Bestandteil dessen, was dazu beiträgt, dass Maschinen funktionieren. Die Antwort darauf liegt in den Details unten, lies weiter und erfahren wir mehr darüber!

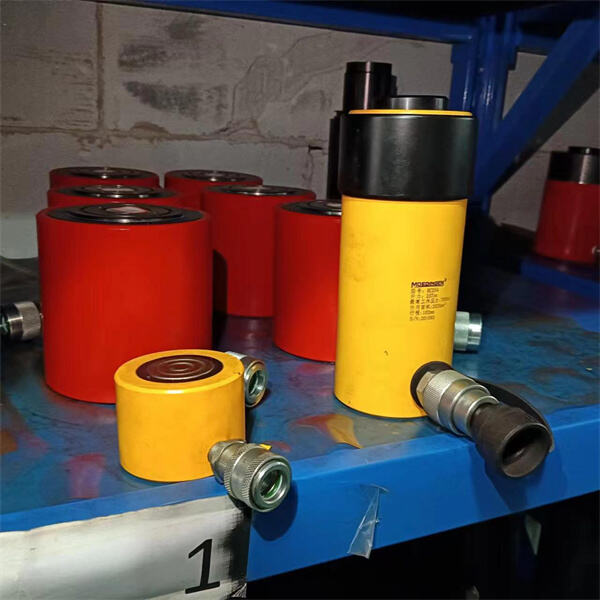

Obwohl 1 2 Hydraulikschlauch beanspruchen sehr wenig Platz, sie sind aber ein mächtiges Werkzeug, das Leitungen mit Motoren verbindet. Stell dir vor, sie sind die Helfer, die dafür sorgen, dass alle Zahnräder im Einklang arbeiten. Sie stellen sicher, dass die Schläuche an ihrem Platz bleiben und flüssige Medien dorthin geleitet werden, wo sie hingehören. Diese Schnittstellen kommen in allen Größen und Formen vor. Dies liegt daran, dass jede Maschine eine bestimmte Art von Anschluss erfordert. Gewinde: Solche Anschlüsse ähneln jenen kunstvoll gedrehten Ried- und Rattanmöbeln. Einige von ihnen haben spezielle Furchen, um sich an Ort und Stelle zu verriegeln. Es gibt eine gemeinsame Aufgabe für alle diese Anschlüsse, unabhängig von ihrer Form oder Größe – die Verbindungen aufrechtzuerhalten und damit den Fluss zu gewährleisten.

Also, wie wählt man die besten hydraulischen Schlauchkupplungen für Ihre Maschine aus. Hier sind einige der wichtigsten Dinge, die Sie beachten sollten, wenn Sie die richtigen auswählen müssen: Zunächst sollten Sie entscheiden, welche Art von Flüssigkeit in der Maschine verwendet wird. Einige Flüssigkeiten sind dick und viskos, während andere so flüssig wie Wasser sind. Natürlich bedeutet das auch, dass Sie eine Auswahl an Kupplungen benötigen, die zur jeweils verwendeten Flüssigkeit passen. Druck der Flüssigkeit: Bevor Sie bestellen, sollten Sie wissen, welchen Druck Ihre Flüssigkeit hat, oder nicht? Zum Beispiel, falls es einen hohen Druck gibt, müssen Sie möglicherweise eine robuste Kupplung bestellen, damit sie den Druck aushalten kann, ohne zu bersten oder Wasser/Luft zu verlieren. Es ist ähnlich wie das Auswählen der besten Schuhe und Kleidung fürs Laufen oder Sport – Sie müssen sicherstellen, dass sie gut passen und gut bei der Arbeit einsetzbar sind!

Hydraulische Schlauchkupplungen sind genauso wie jeder andere Teil Ihrer Maschine – sie müssen gewartet werden, wenn Sie möchten, dass sie ordnungsgemäß weiter funktionieren. Mit der Zeit kann es vorkommen, dass sie abgenutzt oder beschädigt werden und das Dichtungselement anfängt zu lecken, wenn es nicht sogar aufbricht. Deshalb sollte die Wartung und regelmäßige Überprüfungen, um sie in bester Verfassung zu halten, immer auf unserer To-Do-Liste stehen. Ersetzen Sie diese durch neue, wenn Sie feststellen, dass sie Probleme haben. Diese Produkte färben sich ab, wenn Sie nicht vorsichtig sind, was bedeutet, dass sie schmutzig aussehen. Darüber hinaus stellen Sie sicher, dass die Wellen genügend Fett oder Schmierstoff erhalten, um reibungslos zu arbeiten. Wenn Sie eine Kupplung ersetzen müssen, stellen Sie einfach sicher, dass Sie die richtige für Ihre spezifische Maschine verwenden.

Beim ersten Mal könnte die Installation von Hydraulikschlauchkupplungen einigen Menschen einfach erscheinen, aber sie muss genau sein. Die falsche Installation der Schläuche kann dazu führen, dass sie während des Betriebs der Maschine lecken oder sich lösen. Das kann katastrophal sein und zu vielen anderen Problemen führen. Wenn Sie die Dokumentation durcharbeiten und einige einfache Schritte finden können, ist das sehr gut. Aber ja, wenn es im Allgemeinen schwierig ist, dann seien Sie bereit, viele solcher Übungen durchzuführen. Wenn Sie unsicher sind, fragen Sie einen Erwachsenen um Hilfe. Er wird Ihnen zeigen, was zu tun ist, und sicherstellen, dass alles sicher abgeschlossen wird!!!

Schließlich lieben wir es, uns daran zu erinnern, dass Schläuche ein kritischer Bestandteil von Dutzenden verschiedener Arten von Maschinen sind. Sie betreiben alles, von Baggermaschinen und Ausgrabungsgeräten, die im Bauwesen verwendet werden, bis hin zu Flugzeugen und Autos. Diese mechanischen Anschlüsse ermöglichen es diesen Maschinen, Flüssigkeiten zu bewegen und ihre Funktionen auszuführen; ohne sie gäbe es in vielen Fällen überhaupt keine Möglichkeit, Dinge zu transportieren. Also, das nächste Mal, wenn du eine große Maschine siehst, denke daran, wie hydraulische Schlauchanschlüsse ihrer Funktionsweise helfen.