Certaines personnes peuvent se référer au manuel d'une pompe hydraulique. Cela semble vraiment complexe, mais sérieusement, ce n'est rien de plus qu'un livre de référence pour décrire un type de pompe. Ces pompes créent une pression et fournissent un débit en utilisant un liquide constant. Ce texte vous aide à comprendre les différents types de pompes hydrauliques, comment elles fonctionnent et aussi les méthodes pour les utiliser correctement.

On pourrait penser que les pompes hydrauliques sont complexes et sophistiquées, mais en réalité, le mécanisme est simple. C'est la pompe hydraulique qui crée une pression pour faire circuler ce fluide, appelé huile hydraulique. Celle-ci est ensuite transmise sous forme d'énergie mécanique pour déplacer d'autres composants tels que des pistons et des cylindres, etc., dans diverses machines. Les pompes hydrauliques peuvent être trouvées dans de nombreuses choses, comme les voitures et les avions, ainsi que dans du matériel de construction comme les bulldozers ou les grues. Elles aident ces machines à déplacer beaucoup de poids de manière très efficace et avec un minimum d'effort.

Vérifiez souvent le niveau d'huile. Tous les composants principaux d'une pompe hydraulique nécessitent de l'huile pour que l'unité fonctionne correctement, donc avoir la bonne hauteur d'huile est crucial. Vous devriez la vérifier au moins une fois par semaine. Puis ajoutez de l'huile pour vous assurer que la pompe peut fonctionner sans accroc.

Changez l'huile de temps en temps. L'huile hydraulique se dégrade et se salit avec le temps. C'est pourquoi l'huile doit être changée à intervalles réguliers ou toutes les 500 heures de fonctionnement, selon ce qui se produit en premier. L'huile ne maintiendra pas seulement la pompe en bon état, elle aide également à prévenir les problèmes ultérieurs.

La pompe fuit de l'huile. Donc, chaque fois que vous remarquez une fuite d'huile de la pompe hydraulique, éteignez-la. C'est un problème qui peut entraîner des ennuis bien plus importants si vous ignorez la fuite. S'il y a une fuite, elle peut provenir d'un joint cassé ou éventuellement d'une pièce mal serrée.

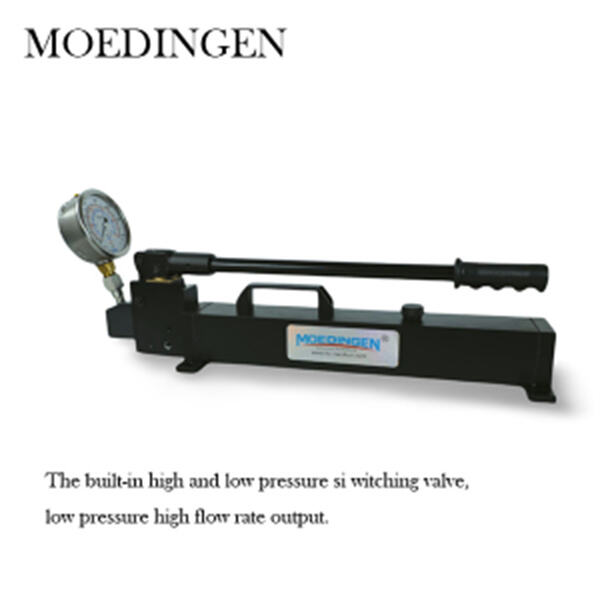

Lorsqu'il s'agit de choisir une pompe, toutes les pompes ne sont pas faites de la même manière. L'un des nombreux aspects à considérer en plus du débit et de la pression est de savoir si elle sera compatible avec votre système. Voici comment choisir la bonne pompe : connaissez votre débit ; le débit est la quantité de fluide que la pompe déplace en un certain temps, ce qui doit être établi avant de sélectionner une pompe pour vous assurer qu'elle sera appropriée à votre usage. Cote de pression ; chaque pompe hydraulique a une cote de pression maximale, qui est la pression maximale à laquelle elle peut fonctionner en toute sécurité. Assurez-vous que la pompe choisie a une cote de pression correspondant à la capacité demandée par votre système spécifique. Adaptation ; la dernière étape est de s'assurer qu'elle s'adapte à tous les autres composants de votre système hydraulique, y compris les flexibles et raccords. La pompe doit être compatible avec tous les composants pour que tout fonctionne efficacement ensemble. Le dernier point est de garantir une sécurité adéquate lors de l'utilisation d'une pompe hydraulique. Cela peut inclure : installer la pompe correctement ; suivez les instructions du fabricant lors de l'installation d'une pompe hydraulique. La pompe doit être solidement fixée et toutes les lignes doivent être vérifiées pour éviter tout incident futur. Porter des équipements de protection ; lors de l'utilisation d'une pompe hydraulique, portez toujours des lunettes de sécurité et mettez des gants. L'huile dans les pompes hydrauliques est extrêmement dangereuse et peut causer des dommages graves en cas de contact avec la peau ou les yeux.

Faites attention aux dangers. Prenez soin lorsque vous utilisez des pompes hydrauliques : même les pompes hydrauliques peuvent être des machines mortelles si manipulées de manière inappropriée. Assurez-vous de garder vos mains éloignées des roues et de toutes les parties en mouvement, car elles travaillent avec des éléments qui, tournant rapidement, pourraient s'avérer dangereux ou fatals.